PDF of EPDM Installation-Manual

Buy EPDM Roofing kits or basic materials from Waterproof Systems

PDF of EPDM Installation-Manual

Buy EPDM Roofing kits or basic materials from Waterproof Systems

Page 1

General Information

This handbook has been designed to give the user a general description of a Plytech supplied fully adhered roof system. It is intended as a broad reference aid and not intended or meant to be all-inclusive.

Prior to installation of a Plytech supplied roof system it is recommended that the installer view the Plytech roof system installation guide. This DVD can be obtained from your Plytech distributor.

Page 2/3

Precautions and Warnings!

Read caution labels on all adhesive, primer and sealant containers. These materials contain petroleum distillates and are extremely flammable. Care must be taken to avoid open flames. Do not smoke when using these products. Product labels, material safety data sheets and technical information sheets contain information for proper use of these products and should be consulted.

Adhesives should be used in a well-ventilated area. Avoid inhalation of fumes. Care should be taken to ensure fumes do not enter the building through windows or fresh-air-intake ventilation fans.

Avoid adhesive contact with eyes. Safety glasses should be worn. If adhesive comes in contact with eyes, flush for 15 minutes and call a doctor.

Avoid adhesive contact with skin. Chemically resistant gloves are required. If adhesive comes in contact with skin, wash with soap and water.

Safeguard against falling by reading ladder manufacturer’s warnings and by establishing a perimeter warning system by using ropes with flags attached. Surfaces can be slippery when wet or covered with frost. Always work with a friend and never work with your back to the roof’s edge. Know and follow OSHA fall protection guidelines. See http://www.osha.gov

Care must be taken with fasteners that penetrate a deck to avoid contact with plumbing or electric wiring.

Reroofing ALL wet materials should be removed for the best results.

Reeroofing over a wet substrate is not good roofing practice and will have poor results.

Condensation may occur when applying Bonding Adhesive at temperatures below 4.5 °C when there is high humidity. If droplets of water are apparent, discontinue installation until weather conditions improve. At that time reapply a thin coat of adhesive over the old coat of adhesive and continue installation.

Allow adhesives to adequately dry to avoid blistering of membrane. Given time blistering will likely go down and roof will perform for the long term.

Positive drainage of at least one-eighth inch 3mm (1/8”) in 300mm (12″) is required for warranty coverage.

Petroleum products such as roof cements and coatings WILL deteriorate EPDM membranes and should NEVER be used on an EPDM membrane roof.

Warranty terms and conditions are on the final pages of the booklet. Note: Plytech supplied adhesives have been tested to insure compatibility with Plytech supplied membranes. Use of other products will invalidate the extended membrane warranty.

Tools Needed

The following list is for reference only, as tools and equipment may vary from project to project:

| 2-inch steel or hard rubber hand roller | Stiff push broom |

| 9-inch paint roller frame & several medium nap, solvent compatible roller covers | Safety glasses and eye cleaning solution |

| Caulk gun | Lumber crayon |

| Screw gun and hammer drill | Hacksaw and blades |

| Solvent resistant rubber gloves | Plytech Scrub Pad |

| Stir stick for adhesives | Tin Snips |

| Scissors & tape measure | Hammer |

| Sand paper for metal drip edge | Duct tape |

| Chalk Line | Cotton rags |

| UL approved can for solvents | Fire extinguisher |

| Utility Knife | Paper hole punch |

Page 4 onwards

Plytech Products Available

1.14mm and 1.52mm EPDM Roofing Membrane:

Synthetic rubber (Ethylene Propylene Diene Monomer) membrane used for flat and low-sloped roofs. .060 inch is recommended for roofing as it is easier to install in a fully adhered application without getting wrinkles in the membrane. 1.14mm thick may also be used as a roofing membrane however this thinner gauge membrane is not recommended for the first time installer.

Plytech membrane panels come in a variety of sizes: as small as (3.048 mtrs) 10′ x (7.62 mtrs) 25′, as large as (12.19 mtrs) 40′ x (30.48 mtrs) 100′ and almost any size in between. For your convenience, smaller rolls are folded and rolled on (1.829 mtrs) 6′ cores. Larger rolls are on (3.353 mtrs) 11′ cores.

Approximate weight of EPDN membrane is 30 lbs. and 40 lbs. per 100 sq. ft. for .045 inch and .060 inch, respectively. Plytech 1.52mm membrane has a 30-year warranty while 1.14mm only has a 20-year warranty. EPDM membrane has many other uses, most notably as a flexible pond lining material.

SOLVENT BASED BONDING ADHESIVE:

Used to adhere EPDM membrane to insulations (excluding polystyrene), plywood, OSB, concrete, block or brick. This yellow coloured adhesive comes in 3.785 litre or 18.9 litre cans. Average coverage is (18.29 sq. mtrs) 60 sq. ft. 3.785 litres . Coverage may increase depending on the porosity of the substrate. Apply Solvent Based Bonding Adhesive by rolling to clean, dry, grease free surfaces. Both surfaces to be bonded must be coated with the bonding adhesive. An open time of five to thirty minutes is recommended before assembly depending on ambient conditions. The adhesive should be allowed to dry until it does not stick to a dry finger touch. Toluene is excellent for post application clean up. Avoid prolonged and repeated contact with skin. Shelf life is 1 year when stored at temperature no higher than 32.2°C in unopened containers.

WATER BASED BONDING ADHESIVE: A user friendly bonding adhesive used to bond EPDM to a porous rigid board substrate such as plywood or wood fibreboard. Solvent based Bonding Adhesive is recommended when using OSB Board.

Water Based Bonding Adhesive has an advantage over Solvent Based Bonding Adhesive as it needs to be applied to only one surface when bonding to plywood and wood fibreboard and the EPDM membrane can be laid onto the adhesive without waiting for the adhesive to dry. With this adhesive you can reposition the membrane during installation thus wrinkles are easily eliminated. As the adhesive does not cure for 24 to 48 hours, be careful not to move the membrane when walking on it. This adhesive is applied at a rate of 2.5mm – 3mm that is (30.48 – 36.58 sq. mtrs) 100 – 120 sq ft and should not be used to seam EPDM panels together. Care must be taken to ensure this product does not freeze and it can only be applied when temperatures are 40°F/22.22°C and above and with no chance of temperatures below freezing within the next 48 hours.

Follow all label directions and precautions. Shelf life is approximately 1 year when stored in a warm room with temperature range between 40°F/22.22°C and 80°F/44.44°C. This material should not be allowed to freeze. If the product looks like cottage cheese when opened it should not be used.

SEAM TAPE PRIMER PLUS: A solvent-based primer designed to clean and prime EPDM membrane prior to application of tape products. Tape products will not adhere, or perform over time, if Seam Tape Primer Plus is not used. Seam Tape Primer Plus must be applied with a Plytech Scrub Pad.

It is also recommended for used in cleaning membrane surfaces when using Rubber to Rubber Adhesive as it enhances the bonding of the membranes, compared to using Membrane Cleaner. Seam Tape Primer Plus can be used on galvanized steel, stainless steel, and aluminium/metal drip edge in conjunction with the application of tape products on these surfaces.

Membrane surfaces must be clean, dry and free of foreign materials. Excessively dirty membranes should be cleaned with Membrane Cleaner and a clean rag. Seam Tape Primer Plus should be THOROUGHLY stirred before use as the suspended solids tend to settle to the bottom of the container. During use, re-stir frequently (every 15 – 20 minutes). The primer must be used full strength – DO NOT DILUTE.

Seam Tape Primer Plus contains ingredients which could be harmful is mishandled. It is important to read and follow all label safety instructions. It is important to store product in the original, unopened container, indoors, and out of direct sunlight at temperatures below 44.44°C/80°F. The shelf life is approximately 24 months if stored in original unopened containers at temperatures between 33.33°C/60°F and 44.44°C/80°F. Rotate stock.

SEAM TAPE:

A butyl tape used to adhere one membrane to another. Available in 3” x 7.62 mtr and 3” x 30.48mtr rolls for roofing applications and also 6” x 30.48mtr rolls for landscape/pond lining applications. Seam Tape has been formulated to provide high initial strength in both sheer and peel. Its performance over the full range of rooftop weather is unsurpassed as it is unaffected by heat or cold. Seam Tape Primer Plus must be applied to the membrane surface, with a Plytech Scrub Pad, prior to applying the Seam Tape. Roll entire surface with a steel hand roller after mating the surfaces. Lap Caulk is not required when using Seam Tape. Seam Tape is a cured material and will not degrade in normal warehouse storage. In time, the release paper may become difficult to remove and, for this reason, the recommended shelf life is 12 months.

CURED COVER STRIP WITH TAPE:

Cured Cover Strip with Tape comes in rolls 5″ x 7.62mtrs, 5″ X 30.48mtrs and 6″ x 30.48mtrs. The product is a laminated, cured EPDM membrane and butyl tape rolled on a release paper and used as a “self-sticking” cover strip. Cured Cover Strip with Tape is a black EPDM rubber based product developed for use with the Plytech supplied EPDM roofing membranes. Cured Cover Strip with Tape is used to cover cuts in the field membrane or over the exposed fasteners attaching metal drip edging. Surfaces should be primed with Seam Tape Primer Plus before installation and should be rolled with a steel hand roller after installation. Cured Cover Strip with Tape will not degrade in normal warehouse storage. In time, the release paper may become difficult to remove and for this reason, the recommended shelf life is 12 months. Cured Cover Strip with Tape is also used to repair membrane if it is damaged by falling debris etc. Be certain to clean the area to be repaired with Membrane Cleaner and prime with Seam Tape Primer Plus using a Plytech Scrub Pad.

UNCURED FLASHING WITH TAPE:

Mouldable EPDM membrane is used for flashing details, protrusions, T-Joint patches and field seams incorporating angle changes. Uncured flashing has the same ingredients as the field sheet. The only difference is it was never put in an oven and cured. Because it is uncured it can be moulded into the shape of inside and outside corners, pipe flashings, etc. The heat of the summer sun will cause the flashing to cure in much the same manner as the field sheet. Uncured Flashing with Tape has a self-adhesive backing and should be applied using Seam Tape Primer Plus. Uncured Flashing with Tape comes (_______________deleted________________) in rolls (12″ x 7.62mtrs, 9” x 15.24mtrs and 6″ x 30.48mtrs). Store in the original unopened packaging at temperatures between 33.33°C/60° F and 44.44°C/80°F, until ready for use. During hot weather, do not expose to sunlight or high temperatures until ready for use. Uncured Flashing with Tape will begin to cure even while on the warehouse shelf. For this reason, the recommended shelf life is 12 months. If the flashing has cured while in the warehouse, it will not work as a mouldable flashing material, however if may still be used as cure cover strip. In time, the release paper may become difficult to remove.

MEMBRANE CLEANER:

Used to clean EPDM surfaces before using Rubber to Rubber Adhesive and also Metal Drip Edge prior to installing Cover Strip with Tape. Membrane Cleaner should be stored in a well ventilated area, at room temperature between 33.33°C/60°F and 44.44°C/80°F in the original sealed explosion-proof container away from all sources of direct heat and ignition. Membrane Cleaner is available in 500mil and 1 US gallon/3.785 litre cans. Membrane Cleaner is extremely flammable and must be kept away from electrical equipment, sparks, open flames and other sources of ignition. Avoid breathing vapours and use only in well-ventilated areas. Handle with impervious gloves and goggles.

RUBBER TO RUBBER ADHESIVE:

A synthetic based polymer adhesive that is specifically formulated to adhere EPDM sheet roofing to itself. Rubber to Rubber Adhesive has long been used for seaming membrane panels but the introduction of tape products for seaming membrane has proven to be more user-friendly and superior for long term performance. It is highly recommended that tape products be used where possible.

For added bond strength it is recommended that Seam Tape Primer Plus be applied with a Plytech Scrub Pad in place of the Membrane Cleaner. In this case membrane cleaner need not be used unless the membrane is excessively dirty or covered with talc. Lap Caulk must be used to seal all seams.

Coverage rate for a 6″ seam, assuming a 7″ application on each surface, is approximately 90 LF per US gallon/27.43mtrs per 3.785 litres of finished seam. For rubber-to-rubber flashing, coverage is 50 to 60 sq ft/15.24 – 18.29 sq mtrs of finished surface per US gallon/3.785 litres, when applying adhesive to both membrane surfaces. Follow all label directions. Cover cans when not in use. When exposed to lower temperatures restore to room temperature prior to use. Thinning is not possible.

LAP CAULK:

Used to caulk exposed edges of rubber to rubber seams, edges of uncured EPDM flashings, tops of Termination Bars and tops of Pipe Boot Clamps. Approximate coverage is 25ft per 10.3oz/7.62mtrs per 292mil tube. Toluene or Xylene are excellent for post application clean up.

WATER CUT-OFF MASTIC:

Mastic serves as a compression gasket preventing contaminates from accessing the roof system where the membrane has been mechanically terminated. Mastic is applied between the substrate and membrane prior to installing Termination Bars and Pipe Boot Clamps. Coverage is approximately 20ft per 10.3oz/6.096 mtrs per 292mil tube. Can also be used as a temporary overnight sealant or water-stop.

TERMINATION BAR:

5′ or 10′/1.524 or 6.096mtr lengths of aluminium with holes 6”s O.C.(on centre) used to mechanically secure membrane at walls, curbs, chimneys, etc. May be used in lieu of metal drip edge on fascias. All holes in a Termination Bar must be filled with appropriate fasteners.

PEEL-AND-STICK PIPE BOOT:

Multi-size (1″ to 6⅞” diameter/254mm to 175mm), pre-moulded, EPDM boot used to flash pipes. Peel-and-Stick Pipe Boot is supplied with tape backing and release paper applied to bottom flange. Pipe Boot should be terminated at top with stainless steel Pipe Boot Clamps, which are included with the product.

SCREWS (2⅝”/665mm) AND PLATES:

There are 250 each Phillips truss head screws with No.3 recess and 3”/76mm plates in each box. Screws and plates are used to install insulation board to the roof deck. The fastening pattern should be one set (screw and plate) to every 2 sq ft/0.6096mtrs of insulation board for the perimeter of the roof and one set to every 4 sq ft/1.22mtrs of insulation board for the remainder. See the “Roof Surface Preparation” section in this manual for the proper fastening pattern. Other sizes of screws and assembled screws and plates are also available.

SCRUB PAD:

This is a specially designed pad and handle that is used to roughen the membrane surface and apply Seam Tape Primer Plus without the user coming in contact with the primer. Its use is highly recommended.

STEEL HAND ROLLER:

This is a specially designed hand roller that is of sufficient weight to roll seams without tiring the user. Its use is highly recommended.

WALKWAY PADS:

These are 30″ x 30″/0.762 x 0.762mtrs skid resistant, moulded EPDM pads that can be stuck to the membrane in much the same manner as laying tile. These pads come with a peel and stick tape for ease of installation. They are used on lower traffic areas and are often used for walk out decks to protect the EPDM membrane.

Plytech add new products on a regular basis to enhance your roofing experience. Ask your distributor for a current list.

Roof Surface Preparation

EPDM roof membrane will adhere to certain isocyanurate insulation boards compatible with Plytech adhesives. Solvent based adhesive will melt the polystyrene. Water based adhesive will not adhere to polystyrene. The roof membrane will also adhere to plywood, OSB (Oriented Strand Board), and 1/2″/13mm high-density wood fibreboard and concrete. Polystyrene insulation may not be adhered directly to rubber membrane. If polystyrene insulation is used, cover insulation with 1/2″/13mm high-density wood fibreboard. Butt all insulation boards together, staggering all of the joints. Any spaces larger than ¼”/6.5mm of an inch/25.4mm must be filled to provide a uniform, smooth surface.

Screws and deck plates should be applied at the minimum rate of 8 per 4ft x 8ft sheet of insulation, and 5 per 4ft x 4ft/1.22 x 1.22mtr sheet or as required by the insulation manufacturer. When installing insulation around the perimeter, the fastening pattern is 1 screw and 1 deck plate every 2 sq ft/0.61mtrs (that is 16 per 4ft x 8ft sheet/1.22 x 2.44mtrs). Examples of fastening patterns are shown in Figure 1. NOTE: Extra fasteners should be installed around protrusions such as pipes, chimneys, skylights and irregularities in the roof deck.

Do not install more insulation than can be covered with EPDM membrane by the end of the day.

Reroofing over a wet substrate is not good roofing practice. All wet material should be removed and replaced.

The roof surface must be dry. Moisture will cause poor membrane adhesion and blistering.

The roof surface should be swept to remove dirt, dust and other loose particles.

Good roofing practice dictates that the roof surface must have positive drainage of at least ⅛” in 12”/3mm in 30.48cms.

Figure 1 — Fastening Pattern

Laying Out RUBBERALL® EPDM Membrane

Unroll the EPDM membrane over the substrate so that the sheet is in the desired position and is wrinkle free. If more than one sheet of membrane is required always place the first sheet of membrane at the low point on the roof. Subsequent sheets would over lap the prior sheet by at least 4″/10.16cms if using seam tape or 6″/15.24cms if using rubber to rubber adhesive, moving up the roof. Care should be taken to insure membrane overhangs perimeter of the roof at least 3″/7.62cms.

Figure 2

Allow the EPDM membrane to relax. Depending on weather conditions, this could take from 15 to 30 minutes. Use strips of duct tape on the upper edge of membrane to stop the membrane from moving.

Pipe Penetrations

When laying out the field sheets and a pipe is encountered, roll the folded membrane to the pipe. Be sure to maintain the proper alignment of the sheet with the roof edge, wall, and seams. Make a straight cut from the pipe to the nearest edge of the field sheet. Cut a hole to match the diameter of the pipe and roll the field sheet around the pipe. Check the final position of the sheet, making certain the membrane does not bridge up the pipe.

Figure 3

Protrusion In The Roof

When laying out the field sheet and a curb (chimney, skylight, etc.) is encountered, unroll the folded membrane up to the curb while maintaining proper sheet alignment with walls, perimeter edges and other protrusions.

Figure 4

Measure the width and depth of the unit and transfer the corresponding dimensions onto the folded membrane. Draw an X inside the box. Cut the X mark and from one corner cut a straight line to the nearest edge of the membrane. Roll the membrane around the unit, leaving a triangle of membrane turning up all four (4) sides. Using a standard paper punch or scissors, punch or cut a round hole at every angle change of the membrane at the outside corners. (This will prevent the cut in the membrane from continuing.)

After all cuts are made and the membrane has been correctly positioned, fold the membrane back and begin bonding procedures. After the field membrane is complete, bond the triangles up the sides of the unit (chimney, skylight, etc.). Take care to bond the membrane into the angle change so that the membrane is completely adhered. Membrane should travel up the wall at least 12″/30.48cms or to the top of the opening if it is less than 12″/30.48cms.

Figure 5

Adhering Membrane with Solvent Based Bonding Adhesive

Fold the sheet onto itself so that half of the sheet is exposed. Take care to avoid wrinkles.

Figure 6

Open and thoroughly stir the Solvent Based Bonding Adhesive (available in either 1 or 5 US gallon/3.785 or 18.93 ltr containers). Using a solvent accepting paint roller, apply the Solvent Based Bonding Adhesive to the substrate and the EPDM sheet at a rate of 60 square feet per gallon. The adhesive must be applied to 100% of both surfaces in an even coat without globs or puddles. Allow the adhesive to dry to finger touch tacky but not stringy. If the membrane is adhered to the substrate before the adhesive has dried, blisters will form under the membrane. Smaller blisters will normally disappear after a few days without causing the membrane to loosen from the substrate over time.

Fluff air under the top half of the sheet and roll the sheet onto the glued substrate. It is important to roll from the middle of the sheet first, followed by the ends (shown in Figure 3). Do not let the ends of the sheet roll ahead of the middle. This will cause wrinkles. With a stiff broom, lightly brush the fully adhered portion of the sheet to the substrate to insure 100% adhesion. Do not apply to much pressure as to cause the EPDM to wrinkle.

Remove the duct tape from the upper half of the membrane panel. Fold back the remaining unglued portion of the sheet and repeat the process.

Figure 7

If installing more than one sheet, always work up the roof so that water flows over and not against the lapping edges. Allow the next sheet to overlap the one already installed by 3″. Use duct tape to hold this sheet in place. Again lay the sheet back halfway and apply Bonding Adhesive to both surfaces and proceed as you did with the first sheet.

NOTE: Do not apply bonding adhesive to seam areas (see figure 8). Thus no bonding adhesive should be applied to the rubber already installed as well as no bonding adhesive should be applied to the 3″ or 6”/7.62 to 15.24cms overlap on the subsequent sheet. Seam tape primer plus with seam tape is recommended when seaming membrane to membrane.

Hint: If bonding adhesive is in area to be seamed, apply duct tape to adhesive, roll with hand roller and peel off duck tape. If any adhesive remains, repeat process.

Figure 8

Adhering Membrane with Water Based Bonding Adhesive

EPDM Water Based Bonding Adhesive is to be used only for bonding Plytech supplied Membrane and Flashing to underlying roof surfaces, i.e. decking or insulation, walls, penetrations, etc. Water Based Bonding Adhesive is not to be used for field seaming of EPDM Membrane or Flashing. The application of this adhesive should be as follows:

Application to Non-Porous Surfaces Horizontal Surfaces (isocyanurate insulation) and Vertical Walls

Figure 9

Figure 10

Fold the membrane back so that half of the sheet is exposed. Apply 5-6 mils/0.12 – 0.15mm of adhesive to both surfaces and allow it to turn transparent and dry to a finger touch. The membrane can then be folded over the insulation or up the wall. Broom or squeegee the membrane surface to insure good contact of the membrane to the substrate. Coverage rate is approximately 100-120 sq ft per gallon but may vary depending on the job site conditions. Remove Water Based Bonding Adhesive from seam area with damp cloth.

Application to One Porous Horizontal Surface (wood fibreboard, gypsum board, plywood ,OSB)

Fold the membrane back so that half of the sheet is exposed. Apply 10-12 mils/0.25 – 0.30mm of adhesive to the porous substrate only, with a roller. Immediately lay the membrane into the adhesive while wet. If the adhesive has turned transparent, a thin coat of adhesive must be applied to the membrane. Laminating onto one surface while the adhesive is wet will allow for some repositioning of the membrane prior to the adhesive setting. Immediately broom or squeegee the membrane after it is laid into the adhesive to insure good contact. Coverage rate is approximately 120 sq ft/36.58mtrs per US gallon/3.785ltrs but may vary depending on job conditions. Remove Water Based Bonding Adhesive from seam area with damp cloth.

Figure 11

Figure 12

Figure 13

Seaming Membrane Panels with Seam Tape

After adhering the membrane sheets so that the width of the seam is the width of the seam tape used, remove excess chalk from a chalk line by snapping the line into the air and then chalk a line 1/2″/13mm from the leading seam edge.

Figure 14a

Fold the top sheet back to expose the seam area. (Hint: A small piece of seam tape that is tacky on both sides is useful to tack the membrane back.) If the EPDM membrane is contaminated with dirt, dust or debris, clean the seam area with Membrane Cleaner on a cotton cloth before applying Seam Tape Primer Plus. Using the Scrub Pad, apply the Seam Tape Primer Plus to the area with back and forth strokes and moderate pressure until the seam surface attains a smooth black appearance. Apply the Seam Tape Primer Plus past the seam edge to the chalk line. Allow the primer to dry.

Figure 14b

If Solvent Based Bonding Adhesive is in area to be seamed, apply duct tape to adhesive covered membrane area and roll with hand roller. Peel off duct tape. If adhesive remains repeat process. If is in area to be seamed, remove with damp cloth.

Seam Tape comes in rolls of 3″ x 25′/7.62cm x 7.62mtrs and 3″ x 100′/7.62cms x 30.48mtrs.

Unroll the Seam Tape along the length of the seam, tape side down, aligning the Seam Tape paper with the chalk line. Using moderate pressure, draw the Scrub Pad or roller along the Seam Tape release paper. This will set the Seam Tape into place and keep air from being trapped under the tape. Fold the top membrane onto the Seam Tape release paper.

Figure 14c

Reaching under the top ply of membrane, pull the release paper away from the Seam Tape at a 45° angle to the seam. While removing the paper, draw your hand across the seam, from the back to the leading edge. This will prevent wrinkles and fish mouths from forming in the seam. After the paper is removed, roll the entire length of the seam with a steel hand roller, first, across the seam, and then the length of the seam.

Figure 14d

IMPORTANT! If the Seam Tape does not visibly extend beyond the leading seam edge, the edge (figure 14d) should be cleaned with Membrane Cleaner and caulked with Lap Caulk.

Note: When splicing Seam Tape, overlap each piece a minimum of 1″/25mm and firmly roll with a steel hand roller.

Splicing and Seaming with Rubber To Rubber Adhesive (Seam Tape Is Recommended Where Possible)

Fold the top ply of the seam back to expose the 6″ /15.24cms area to be seamed. Remove any bonding adhesive as noted in the previous section. Using a clean cotton rag, clean both surfaces at the splice area with Membrane Cleaner at a maximum rate of 200 lineal ft/30.96mtrs per US gallon/3.785ltrs. Be sure to clean a minimum of 1″/25mm past the leading edge of the finished seam.

When cleaning the seam area, change the rags frequently. Do not allow the rags to become loaded with talc or other contaminants from the membrane.

WARNING: Membrane cleaner is extremely flammable!! Use UL Approved containers.

Figure 15a

Figure 15b

Figure 15c

Rubber to Rubber Adhesive should be applied at a maximum rate of 130 – 140 lineal feet/36.62 – 42.67mtrs per US gallon (8 – 10 mils/0.20 – 0.25mm’s thick when dry). Allow the Rubber to Rubber Adhesive to dry to the finger touch (tacky not stringy).

IMPORTANT: When cleaning and applying rubber to rubber adhesive to the seam area, be sure to extend both procedures past the leading edge of the finished seam.

Starting in the middle of the seam, fold the top ply onto the bottom ply, working from the middle to the ends of the seam. Make sure to avoid wrinkles and fish mouths. Using a steel hand roller, roll the entire length of the seam from the middle toward the ends of the seam, then rolling parallel with the seam.

Clean the seam edge with Membrane Cleaner and apply a 1/4″/6.35mm bead of Lap Caulk centred over the seam edge. Make sure the caulk covers both the upper and lower parts of the seam membrane.

Note: Applying Lap Caulk should be the last application procedure. It is advisable to wait at least 4 hours after completing the seaming procedure before application. Applying Lap Caulk before the seams cure might cause the seam edge to distort and pucker.

Alternative Panel layout and Seaming

The following seaming technique is acceptable for only fully adhered roofs.

Lay roof panels out with at least a 2″/50.8mm overlap. Fully adhere roof as instructed earlier. After the roof is adhered, use a straight edge and utility knife to cut through both layers of membrane in the area where the panels are overlapped. Remove the end cuts from both panels. This procedure creates a perfect butt splice in the same manner as a wall paper hanger would.

Figure 15d

Using a Scrub Pad and Seam Tape Primer Plus prime an area 4″/10.16cms on either side of the butt splice. Centre 6″/15.24cms Cured Cover With Tape over the butt splice and unroll while removing the backing paper. Roll the cover strip with a steel hand roller, first rolling the length of the seam and then across the seam.

Figure 15e

Perimeter Walls & Inside Corners

Stick the field sheet to the substrate until the membrane reaches the wall. Apply Bonding Adhesive to the folded membrane and the wall area. Starting at the base or angle change between the corner and opposite end of each wall, begin to roll the EPDM sheet up and along the wall to form a wall flashing. Roll the excess EPDM material towards the corner. Take care to thoroughly stick the membrane into the angle change before rolling the membrane up the walls. Broom or hand rub the flashings to ensure 100% adhesion.

Note: Wall Flashings should extend a minimum of 12″/30.48cms above the roof deck.

Figure 16

When one side is flashed in, (A), begin the other side, (B). When both walls are flashed in, all excess material should form a pocket in the corner.

Clean the inside and outside of the pocket with Membrane Cleaner and apply Rubber to Rubber Adhesive to both sides of the pocket. Allow the adhesive to dry, tacky to the touch but not stringy.

Figure 17

Note: It is important to bond the wall flashing on each side of the corner as tightly into the corner as possible.

Starting at the base of the inside corner pocket, press the two glued surfaces together. Following standard seaming procedures attach the pocket to either wall (see Figure 12). Install a 6″/15.24cms Cured Cover Strip with Tape extending from the bottom of the pocket fold to the top (see Figure 23).

Figure 18

Outside Corner Finish Detail

Figure 19 a

Figure 19 b

Figure 19 c

Uncured Flashing with Tape comes in Patches (12″ x 12″/30.48 x 30.48cms) and rolls (12″ x 25’/30.48cms x 7.62mtrs or 6″ x 100′/15.24cms x 30.48mtrs).

IMPORTANT: All stretching should be done in the middle of the flashing.

IMPORTANT: Always extend the new flashings above any existing membranes or flashing materials.

Cover Strip

Where a protrusion in the roof, such as a pipe or curb opening, was encountered while installing the EPDM membrane, the membrane was cut to the nearest edge to allow easy layout of the membrane. After the field sheet has been glued and brushed into place, apply a 6″/15.24cms wide Cured Cover Strip over the entire cut in the field sheet from the pipe to the end of the sheet, prior to pipe boot installation.

Figure 20

Peel and Stick Pipe Boot

Figure 21

Pipe or Conduit Flashings using Uncured Flashing with Tape

When a pipe or conduit is encountered that cannot be flashed with a Peel and Stick Pipe Boot, the protrusion must be flashed using 2-plys of Uncured Flashing with Tape.

Note: It is recommended to extend the flashings above the roof deck a minimum of 8″/20.32cms. Wrap the entire protrusion with another ply of Uncured Flashing with Tape to attain the desired height. Make sure to overlap the top of the prior ply a minimum of 2″/50.8mm.

Always extend the new EPDM flashings above any old flashings that may remain on the protrusion. Clean and apply Lap Caulk to the flashings. Do not install a Pipe Boot Clamp over Uncured Flashing with Tape.

Figure 22

Wall Termination

Always extend the membrane up the wall a minimum of 12″/30.48cms. When using wood shakes, or other siding materials, a Termination Bar is not required if the siding material is brought down at least 8″/20.32cms below the top of the EPDM sheet. All siding must be kept a minimum of 4″/10.16cms above the roof deck.

Determine the height of the finished wall flashing (12″/30.48cms height or less if job conditions won’t allow) and the placement of the aluminium Termination Bar. Chalk a line at this level. Peel the top of the wall flashing from the wall to the chalk line and apply a heavy bead of Water Cut-Off Mastic between the EPDM and wall. The mastic should be applied so that the final position of the Termination Bar will be directly over the Water Cut-Off Mastic.

Fasten the Termination Bar with nylon/metal anchor pins, or aluminium sheet metal screws. Install a fastener in every pre-drilled hole. Remove excess membrane that extends above the Termination Bar and apply Lap Caulk to the top of the Bar.

Figure 23

Termination bar comes in 5′/1.524mtrs and 10′/3.048mtrs lengths.

T-Joints

A T-Joint is formed when two sheets of cured EPDM form a seam that travels under, or over, a third ply. The centre of the “T” is where the middle sheet ends and the top sheet bridges over the middle sheet. This T-Joint can provide an opportunity for water to seep under the membrane. To avoid this problem a T-Joint patch should be installed as follows:

Figure 24 — Areas where T-Joint patches are required:

Figure 24 a – Where a field seam travels under a wall flashing.

Figure 24 b – Where a cover strip travels under a pipe boot or other flashing.

Figure 24 c – Where a horizontal seam will lap over, or traverse a vertical seam.

IMPORTANT: Only Uncured Flashing with Tape, cut to size, should be used for T-Joint patch. All T-Joint patches should be thoroughly rolled with a steel hand roller.

Field Seam Radical Bend

Where a field seam makes a radical bend (turns up a wall or down over a perimeter edge), a 6″/15.24cms wide by 12″/30.48cms) long piece of Uncured Flashing with Tape should be fixed over the seam. Round the corners of the Uncured Flashing with Tape to prevent accidental peeling. Following standard flashing procedures, install the flashing so that half of the flashing is on either side of the radical bend.

Figure 25

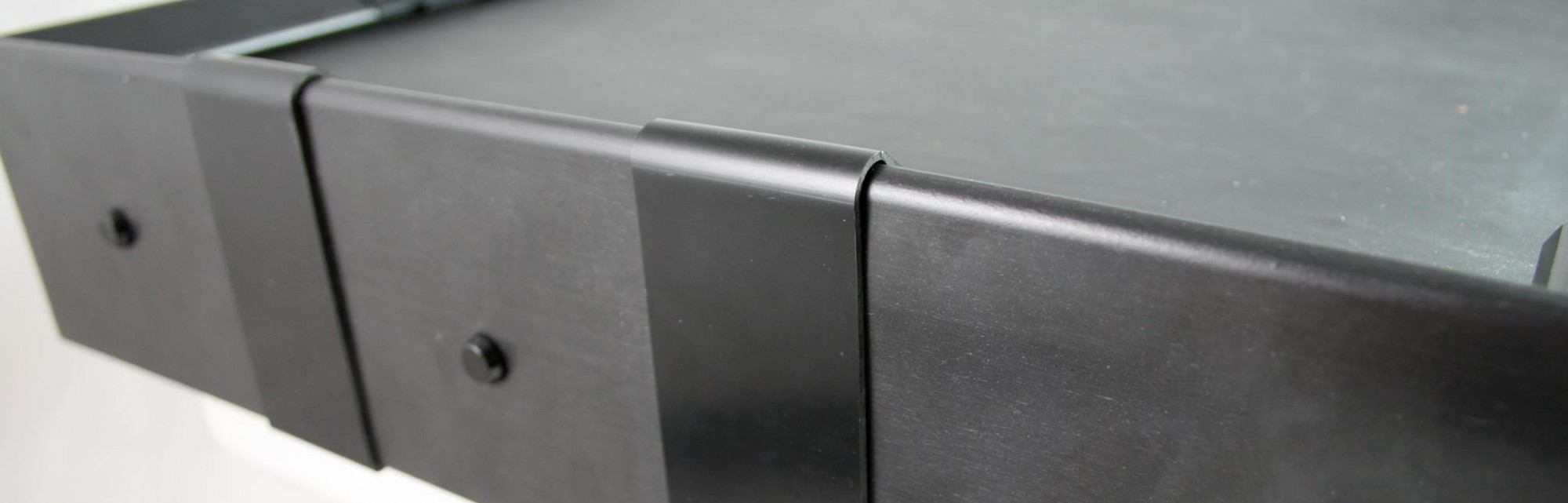

Roof Edge Termination with Metal Drip Edge

Fully bond the membrane over the roof edge. Allow the membrane to extend past the previous roofline and nail it every 4′/1.219mtrs centrally.

Prior to installing the metal drip edge, sand the metal with sand-paper. Install using galvanized deck screws or galvanized ring shank nails every 6″/15.24cms centrally.

Figure 26

Using Membrane Cleaner and a clean cotton cloth, clean the metal and the membrane to be seamed. Using a Plytech Scrub Pad, apply the primer to the metal and field membrane using back and forth motions along the entire length of the metal edge. To ensure 100% adhesion, always apply the primer to an area that is wider than the Cured Cover Strip with Tape. After the Seam Tape Primer Plus has flashed off, install the Cured Cover Strip with Tape ½”/13mm in from the outside edge of the metal drip edge. Roll the entire cover strip with a small hand roller.

When splicing two pieces of Cured Cover Strip with Tape, allow for a minimum lap of 4″/10.16cms. After properly rolling the entire Cover Strip, install a 6″/15.24cm Uncured Flashing with Tape over any T-Joints.

Terminating RUBBERALL® On Fascia

Bring the EPDM membrane over edge of roof by approximately 4″/10.16cms. Where the membrane wraps over an inside or outside corner to create a flap. Then tack to one side of the fascia with a roofing nail. Using a Termination Bar, in either 5′ or 10′/1.524mtrs or 3.048mtrs lengths, and an appropriate length screw, secure the Termination Bar with a screw in every hole. Leave a ¼”/6.35mm gap between Termination Bars for expansion.

A Termination Bar can easily be bent around an outside corner. With a utility knife cut excess membrane from the bottom side of the Termination Bar and apply a bead of Lap Caulk to the top. It is also advisable to put a spot of Lap Caulk over each screw to prevent water from penetrating around screw and rotting the fascia.

Figure 27

EPDM Membrane To Shingle Transition

When installing an EPDM membrane system with a tie-in to an existing shingle roof, remove a minimum of 3 courses of shingles.

Bond the membrane onto the sloped roof deck. Peel the top of the EPDM membrane back and apply a bead of Water Cut-Off Mastic between the membrane and the deck. Nail the top of the membrane every 6″/15.24cms and install the shingles over the EPDM.

Figure 28

Keep the bottom course of shingles to a minimum of 4″/10.16cm above the roof angle change. To fasten the bottom course of loose shingle tabs to the membrane, lift each tab and apply a 1″/2.54cm long bead of Lap Caulk.

One Piece Drain Sleeve

Drain Sleeve Inserts are used when the existing drain does not have a clamping ring assembly, or cannot be taken up, properly cleaned and incorporated into the new roofing system.

Note: Before beginning the re-roof project, thoroughly clean the existing drain. Do not allow debris to clog the drain pipe. The new Drain Sleeve Insert should be lower than the new roof system surface.

Install the field membrane over the drain. Cut a circle the size of the Drain Sleeve Pipe directly over the existing drain. Following the standard seaming procedure, clean the field membrane and Drain Sleeve Insert with Membrane Cleaner. Apply Rubber to Rubber Adhesive to the field membrane and the bottom of the drain inserts. After the adhesives have flashed off, apply a heavy bead of Water Cut-Off Mastic above each back up ring and at the angle change of the drain bowl. Insert the drain sleeve into the existing drain. If it is necessary to mechanically faster the Drain Sleeve, use the proper length deck screws with 2″/50.8mms or 3″/7.62mms plates.

After the Drain Sleeve Insert has been installed, using standard seaming procedures, install a “target patch” to extend 6″/15.24cms on all sides, past the edge of the Drain Sleeve Insert. Cut the target hole ½”/2.54cms larger than the strainer securing ring.

Clean all seam edges with Membrane Cleaner and apply a ¼”/6.35mm bead of Lap Caulk. Insert the strainer ring into the drain bowl and install the strainer.

Figure 29

Drains with Clamping Rings

If the existing drain has a clamping ring assembly, remove the strainer, clamping ring bolts and clamping ring. Clean the drain bowl, clamping ring flange and clamping ring. Do not allow debris to clog drain pipe.

Install the field membrane over the drain. To determine where to cut the hole, place the drain clamping ring over the membrane onto the clamping ring flange. Allow the membrane to extend 1″/2.54cms past the clamping ring.

After the membrane has been cut, lift the membrane and apply several heavy beads of Water Cut-Off Mastic to the clamping ring flange. It is recommended to use a minimum of ½ tube per drain.

Align the clamping ring over the membrane and punch holes where necessary to install the clamping ring bolts. Do not cut the membrane back to the bolts. Secure the clamping ring and install the strainer.

Figure 30

Pitch Pockets

When installing a metal Pitch Pocket on a reroof project, always install a wooden nailer around the protrusion. The nailer should be wider than the base flange of the Pitch Pocket, and the same thickness as the retrofit or insulation board. Remove any foam insulation wrap to a point above the Pourable Sealer line. To ensure the Pourable Sealer will adhere to the protrusions, clean and apply Rubber to Rubber Adhesive to the protrusion, extending above the Pourable Sealer line.

Bond the membrane up to and around the protrusion. Apply a bead of Water Cut-Off Mastic to the bottom of the Pitch Pocket and secure it to the nailer.

Flash-in the Pitch Pocket using Cured and Uncured membrane or flashing, securing the material past the top of the Pitch Pocket into the inside of the Pocket. Thoroughly mix the Pourable Sealer and fill the Pitch Pocket. Allow for the slope of the Pourable Sealer from the protrusion to the Pitch Pocket.

Figure 31a – New Construction

Figure 31b – Reroof

Protecting RUBBERALL® Membrane In High Foot Traffic Areas (Decks)

IMPORTANT: The EPDM Membrane is not designed as a final walking surface and should be protected from excessive foot traffic. The following are options to be considered:

Covering with Walkway Pads

Plytech Walkway Pads (Peel & Stick) are 30″ x 30″/76.2 x 76.2cms skid resistant, moulded EPDM pads that can be adhered to the membrane in much the same manner as laying tile:

You may also use rubber to rubber adhesive over the entire Walkway Pad and membrane to fully adhere. Refer back to section on rubber to rubber adhesion for more information.

Figure 32

Covering With Wood Deck

When installing a wood deck over an EPDM membrane, the deck sleepers should be laid over an extra piece of membrane called a separator sheet. The separator sheet should extend a minimum of 2″/50.8mms past the sleeper on all sides and should be adhered with Seam Tape.

Figure 33

Do not attach the sleepers through the membrane. The deck should be secured at a side wall, post, or perimeter area.

Covering With Exterior Grade Carpet

When attaching an outdoor carpet, use any exterior grade adhesive and install according to carpet manufacturer’s instructions.

Repair of EPDM Membrane

If your EPDM membrane is punctured, repairs can be made easily by:

(New Page here)

Application Review

Overall appearance is very important.

Frequently Asked Questions

Q – Why do bubbles or wrinkles form after the membrane is fastened?

A – Solvents in the adhesives, which are not allowed to “flash off” or evaporate, cause distortions or bubbles. The wet adhesive distresses the membrane causing wrinkles. Depending on the substrate and the amount of wet adhesive, bubbles or distortions in the membrane will eventually be absorbed by the membrane and disappear.

Q – Can the adhesive dry too long?

A – Yes. After the adhesive is applied and has flashed off, the surfaces should be mated together. Allowing the prepared surfaces to remain open longer than necessary risks contamination from dust and debris. High temperatures as well as falling cool temperatures and moisture can affect the performance of the adhesives if the prepared surfaces are left open too long.

Q – Can I put a deck over an EPDM roof?

A – Yes. See Figure 32 and 33 in this manual.

Q – Can I install outdoor carpet over an EPDM roof?

A – Yes. The best method is to fully attach the carpet using an exterior grade carpet adhesive.

Q – Can I fasten EPDM to concrete or wood?

A – Yes. Both substrates should be free of splinters, burrs, loose fasteners, sharp edges, dust and debris.

Q – Are there warranties for residential applications?

A – Yes. Plytech will furnish free Membrane Warranties for all registered installations using .060″/1.52mm and .045″/1.14mm Plytech EPDM provided all accessories (adhesives, seam tape, etc.) have been supplied by Plytech . Warranty duration is 30 and 20 years for .060″/1.52mm and .045″/1.14mm respectively.

Q – What temperature is too cold for a successful installation?

A – Adhesives perform best at temperatures over + 40°F/22.22°C. Below +40°F/22.22°C it is best to install only on full sun days with low air moisture content. Application may only be possible during the middle part of the day when the temperature is stable and humidity is lowest. Rule of thumb. . . . If it is comfortable to work, you can install EPDM. It just takes longer for the adhesive to flash off.

Q – Can I use Plytech EPDM below grade?

A – Yes. Plytech EPDM can be used below grade as a waterproofing membrane on basement walls, water retention ponds and earth homes. It is important that the substrate be free of burrs and sharp edges that could puncture the membrane. Earth homes and sidewalls should have a barrier board between the membrane and the backfill.

Q – Is Plytech EPDM Membrane safe to use in ponds with aquatic life?

A – Yes, our membrane has been tested and has proven to be “Suitable for Aquatic Life”.

Q – Can I install EPDM over smooth surface asphalt or shingle roofs?

A – Installing EPDM over old smooth surface asphalt or shingles is not recommended. The adhesives used to bond the membrane will activate “dead” asphalt and not bond properly. A retrofit or insulation board should be installed over the old substrate.

Q – When I adhered the membrane, several wrinkles occurred. Will the wrinkles affect the roof?

A -Although wrinkles are unsightly, unless they traverse a seam, they will not leak. Large wrinkles can be cut out and patched. Small wrinkles might be absorbed into the membrane as it goes through several expansion/contraction cycles. Any wrinkles that migrate through a seam must be removed and repaired.

Q – When should I use .045″/1.14mm and when should I use .060″/1.52mm EPDM membrane?

A – .060″/1.52mm membrane is recommended for roofing applications primarily for ease of installation. .045″/1.14mm membrane as a roofing membrane should only be used by the experienced installer. Inexperienced installers will find that they encounter wrinkles when bonding the membrane. Cutting these wrinkles out take time and leaves a less pleasing roof appearance.

The .045″/1.14mm EPDM membrane is the product of choice for water retention ponds, below grade waterproofing and also for many other uses around the home.

Glossary

BONDING ADHESIVE: Bonding Adhesive used to fasten the field sheet to substrate, walls and curbs. It should be thoroughly stirred before using. Adhesives can be either Solvent Based or Water Based Bonding Adhesives.

BRIDGING: Occurs when the membrane is unsupported at a juncture or angle change. Moisture condensing on the bottom of the membrane can cause further de-lamination. Areas where bridging occurs should be repaired and re-flashed.

CURED COVER STRIP: 6″/15.24cms wide cured EPDM membrane with butyl tape laminated to one side. Used when stripping in metal drip edge, repairing cuts in the field membrane or flashing that requires cured membrane.

DECK PLATES AND SCREWS: Used to mechanically attach the insulation board to the roof deck.

EPDM MEMBRANE: Cured field sheet membrane applied to roof decks, walls and flashings. Available in a variety of widths and lengths.

FISH MOUTH: A wrinkle is formed when an increasing amount of membrane is forced onto an area too small to accommodate the material. When the wrinkle ends at the edge of the material, a conical opening is formed called a Fish Mouth. Wrinkles and Fish Mouths in seams are not acceptable. They must be removed and flashed in.

FLASH OFF: Allowing the solvents in the adhesives or primer to evaporate, leaving the material in a tacky, not wet or stringy condition, before mating the two surfaces together. If the proper flash off time is not allowed, blisters will form in the membrane. These will not harm the membrane and over time, will usually disappear.

LAP CAULK: Applied at the top of all Termination Bars; at the top of Pipe Boots after the Pipe Boot Clamp has been installed and to adhere shingle tabs to the EPDM membrane. Lap Caulk must be used when Rubber to Rubber Adhesive is used to bond two pieces of membrane.

MEMBRANE CLEANER: Used for cleaning metal drip edge after it has been sanded, prior to applying Rubber to Rubber Adhesive; cleaning seam edges prior to applying Lap Caulk; cleaning excessively dirty membrane; splicing membrane or inside and outside corner details.

METAL DRIP EDGE: Used to create a finished appearance and prevent water from running down the surface of fascias and walls. Metal Drip Edge is made from painted aluminium and galvanized or painted steel and is available at local builders merchants.

PIPE BOOT: Pre-moulded EPDM boot with tape: The best and most cost effective way to flash pipes.

PIPE BOOT CLAMP: Stainless steel clamp used to secure the top of the pipe to the Pipe Boot.

SEAM TAPE: Butyl tape used to splice two layers of membrane into a watertight seam. Available in a 3″/7.62cms and 7″/17.78cms widths.

SEAM TAPE PRIMER PLUS: Solvent based primer used to clean and prime the EPDM membrane before applying Seam Tape or any cured or uncured tape backed membrane. It is applied using a Scrub Pad. Do not apply primer directly to tape. Primer is only applied to surfaces being prepared to accept tape products. Seam Tape Primer Plus enhances the strength of membrane bonds using Rubber to Rubber Adhesive.

SUBSTRATE: The surface on which the membrane is applied (brick, concrete block, high-density wood fibreboard, plywood, OSB, isocyanurate insulation). Note: The membrane should not be adhered directly to asphalt roofing, shingles or polystyrene insulation.

T-JOINT: A T-Joint is formed when two sheets of cured EPDM form a seam that travels under, or over, a third ply. The centre of the “T” is where the middle sheet ends and the top sheet bridges over the middle sheet.

TARGET PATCH: A piece of membrane used to flash over a roof jack or pipe. A Target Patch is always larger than the object it is flashing in, and is a cured membrane. Note: Do not apply membrane directly to gas furnace stacks.

TERMINATION BAR: Extruded aluminium bar used to terminate the membrane at parapet walls, chimneys, skylights and AC curbs. It is also used to terminate membrane fascia when no metal drip edge is used. The proper fastener should be installed in every hole and a ¼”/6.35mm space maintained between bars.

UNCURED FLASHING WITH TAPE: EPDM membrane that is not cured (meaning it was not put in oven and baked in the manner of cured membrane) and is used whenever the field sheet has to be cut to accommodate outside corners, pipes, T-Joint patch and field seams making angle changes. After Uncured Flashing with Tape is applied, it will cure in the position in which it was applied. It should be applied using Seam Tape Primer Plus.

WATER CUT-OFF MASTIC: Used to create a waterproof compression gasket whenever the membrane is mechanically fastened using a Termination Bar or Pipe Boot Clamp. Water Cut-Off Mastic is applied between the membrane and the pipe or wall. The mechanical termination is installed over the membrane, compressing the mastic and creating the gasket.

Plytech Roofing Membrane Material and Labour Limited Warranty

30 Years on .060 inch/1.52mm membrane (Fully Adhered Roofing Installations Only)

20 Years on .045 inch/1.14mm membrane (Fully Adhered Roofing Installations Only)

Plytech supplied EPDM in a fully adhered roofing installation is warranted against premature deterioration to the point of failure due to weathering of a period of 30 years for .060-inch/1.52mm membrane or 20 years for .045-inch/1.14mm membrane from the date of purchase if installed using Plytech supplied adhesives. (Other than Plytech tested adhesives may cause pre-mature deterioration).

The holder of this warranty must keep receipts showing that both the membrane and adhesives are supplied by Plytech. This warranty is transferable to subsequent owners.

Plytech UK Limited liability is limited to providing replacement membrane and the labour to install a replacement membrane. The value of the credit will be determined on a pro-rata basis. For .060-inch/1.52mm membrane: number of remaining months of the warranty divided by 360 times the value of the replacement membrane and the labour to install. For .045-inch/1.14mm membrane: number of remaining months of the warranty divided by 240 times the value of the replacement material and the labour to install. Replacement accessories, other materials and replacement material shipping costs are not included in this warranty.

If a claim is made the following must be submitted: a current picture of the roof installation showing membrane deterioration; a sample of material said to have deteriorated; and original receipts showing membrane and accessories were supplied by Plytech. We reserve the right to inspect the roof before compensation is made under this warranty. This warranty is voided if the Plytech supplied membrane is removed from the rooftop before a Plytech representative is given the opportunity to inspect the roof for improper use of non-Plytech products or exposure to any of the non-warranted conditions noted below. This warranty does not cover the workmanship of the installer of Plytech products nor does it assure the roof will not leak due to poor workmanship of the installer. This warranty applies only to Plytech EPDM membrane installed on projects that have been registered by posting the registration card or by completing it on the Plytech website. Failure to use an original warranty card or to completely fill in requested information will void the warranty. It is not Plytech’s responsibility to return a card for more complete information. Warranty claims must be made in writing and mailed to Plytech UK Ltd, 41 Marsh Green Road West, Marsh Barton Industrial Estate, Exeter, Devon EX2 8PN.

Plytech UK Ltd shall have no obligation under this warranty for membrane deterioration caused by any of the following:

The remedies stated in this warranty are the sole and exclusive remedies for failure of the Plytech supplied EPDM membrane. There are no warranties, either expressed or implied, including the implied warranties of fitness for a particular purpose and merchantability, which extend beyond the warranties, stated above. Plytech UK Ltd shall not be liable for any direct, incidental, consequential, special or other damages, including but not limited to loss of profits or damage to the building or its contents under any theory of law. This warranty applies to Plytech EPDM membrane purchased after 1st October 2012. Plytech UK Ltd reserves the right to modify and/or withdraw said warranty at its discretion having given advance notification to its distributors.

Warranty Registration

Warranty Registration Cards are available from you local distributor or may be downloaded at http://www.plytech.co.uk.

Complete the card and post it to:

Plytech UK Ltd, 41 Marsh Green Road West, Marsh Barton Industrial Estate, Exeter, Devon EX2 8PN.

You may also register your warranty on line at http://www.plytech.co.uk.

Our new Youtube Video (below) will guide you how to use our Roof Quote Tool. Marc also talks a little about the different options available so very useful for anyone looking to assemble their own kit.